Understanding Bus Adhesive Wheel Balance Weights: Enhancing Vehicle Performance and Safety

When it comes to maintaining the performance and safety of vehicles, particularly buses, one critical aspect is wheel balance. Bus adhesive wheel balance weights are essential components that help achieve this balance, ensuring that the wheels rotate evenly. Uneven weight distribution across wheels can lead to vibrations, increased tire wear, and compromised handling, which are particularly concer

When it comes to maintaining the performance and safety of vehicles, particularly buses, one critical aspect is wheel balance. Bus adhesive wheel balance weights are essential components that help achieve this balance, ensuring that the wheels rotate evenly. Uneven weight distribution across wheels can lead to vibrations, increased tire wear, and compromised handling, which are particularly concerning for larger vehicles like buses that carry significant passenger loads.

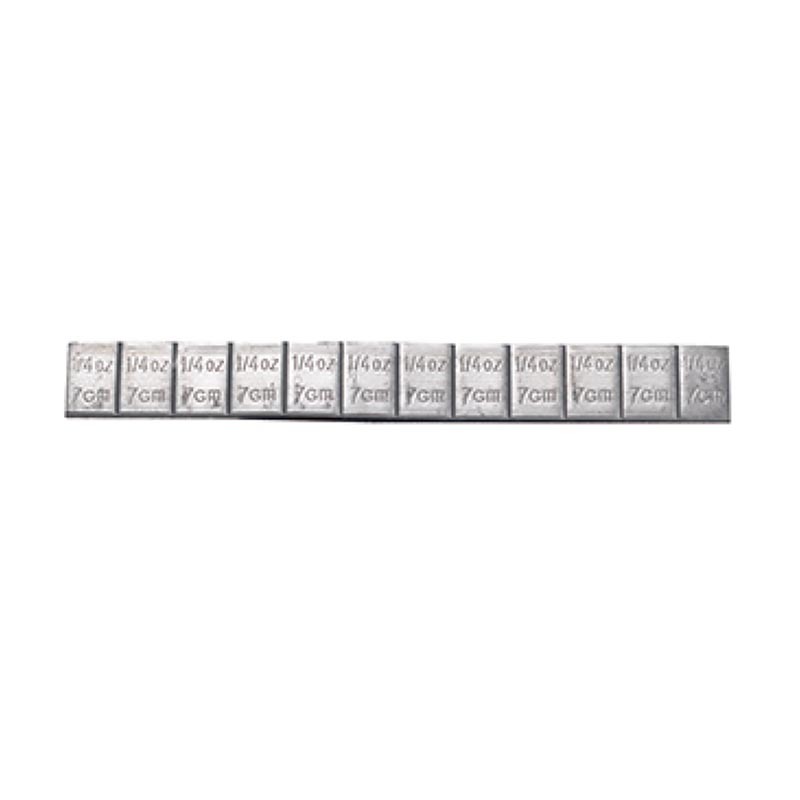

Adhesive wheel balance weights are designed to stick directly to the wheel rim, providing a seamless solution for achieving balance without the need for mechanical fasteners. This installation method not only simplifies the balancing process but also enhances the aesthetics of the wheel, as the weights are less visible compared to traditional clip-on weights.

The correct installation of bus adhesive wheel balance weights is crucial. It is important to ensure that the wheels are clean and free of debris before applying the weights. A precise measurement of wheel imbalance must be conducted using specialized equipment to determine the exact amount of weight needed on each wheel. This process typically involves dynamic balancing, where the wheel assembly is rotated at high speeds to identify any imbalances.

The material used for these adhesive weights is also essential. High-quality adhesive ensures that the weights remain securely attached even under the high-stress conditions that buses often encounter, such as sharp turns, rapid acceleration, and braking. This reliability is vital not only for vehicle performance but also for the safety of passengers.

Regular maintenance and checks are recommended to ensure that adhesive weights remain securely fixed. Any loss or displacement of weights can lead to imbalance, which can cause premature tire wear and negatively impact vehicle handling. Therefore, bus operators should incorporate routine inspections into their maintenance schedules.

Additionally, understanding the benefits of using bus adhesive wheel balance weights can significantly enhance overall vehicle efficiency. Properly balanced wheels contribute to improved fuel efficiency, reduced tire wear, and a more comfortable ride for passengers. In the long run, this translates into cost savings for fleet operators and enhanced safety for everyone on board.

In conclusion, bus adhesive wheel balance weights play a pivotal role in maintaining vehicle performance and passenger safety. Their effective application, coupled with regular maintenance, ensures that buses operate smoothly, efficiently, and safely on the roads. As the automotive industry continues to evolve, the importance of such components remains paramount in the pursuit of excellence in vehicle performance.

Adhesive wheel balance weights are designed to stick directly to the wheel rim, providing a seamless solution for achieving balance without the need for mechanical fasteners. This installation method not only simplifies the balancing process but also enhances the aesthetics of the wheel, as the weights are less visible compared to traditional clip-on weights.

The correct installation of bus adhesive wheel balance weights is crucial. It is important to ensure that the wheels are clean and free of debris before applying the weights. A precise measurement of wheel imbalance must be conducted using specialized equipment to determine the exact amount of weight needed on each wheel. This process typically involves dynamic balancing, where the wheel assembly is rotated at high speeds to identify any imbalances.

The material used for these adhesive weights is also essential. High-quality adhesive ensures that the weights remain securely attached even under the high-stress conditions that buses often encounter, such as sharp turns, rapid acceleration, and braking. This reliability is vital not only for vehicle performance but also for the safety of passengers.

Regular maintenance and checks are recommended to ensure that adhesive weights remain securely fixed. Any loss or displacement of weights can lead to imbalance, which can cause premature tire wear and negatively impact vehicle handling. Therefore, bus operators should incorporate routine inspections into their maintenance schedules.

Additionally, understanding the benefits of using bus adhesive wheel balance weights can significantly enhance overall vehicle efficiency. Properly balanced wheels contribute to improved fuel efficiency, reduced tire wear, and a more comfortable ride for passengers. In the long run, this translates into cost savings for fleet operators and enhanced safety for everyone on board.

In conclusion, bus adhesive wheel balance weights play a pivotal role in maintaining vehicle performance and passenger safety. Their effective application, coupled with regular maintenance, ensures that buses operate smoothly, efficiently, and safely on the roads. As the automotive industry continues to evolve, the importance of such components remains paramount in the pursuit of excellence in vehicle performance.

TAG:

Related Posts

Global automotive wheel balance block industry

The global market size of automotive wheel balance weights in 2024 is approximately 4.92 billion yuan. It is expected to maintain a steady growth trend in the future