The Advantages of Zinc Stick-On Weights for Aluminum Rim Enthusiasts

The Advantages of Zinc Stick-On Weights for Aluminum Rim Enthusiasts

Table of Contents

Introduction to Zinc Stick-On Weights

What are Zinc Stick-On Weights?

Benefits of Using Zinc Stick-On Weights

Durability and Longevity

Performance Enhancements

Ease of Installation

Environmental Impact of Zinc Weights

The Advantages of Zinc Stick-On Weights for Aluminum Rim Enthusiasts

Table of Contents

- Introduction to Zinc Stick-On Weights

- What are Zinc Stick-On Weights?

- Benefits of Using Zinc Stick-On Weights

- Environmental Impact of Zinc Weights

- Comparison to Other Weight Materials

- Applications in the Automotive Industry

- Maintenance and Care for Zinc Weights

- Conclusion

- Frequently Asked Questions

Introduction to Zinc Stick-On Weights

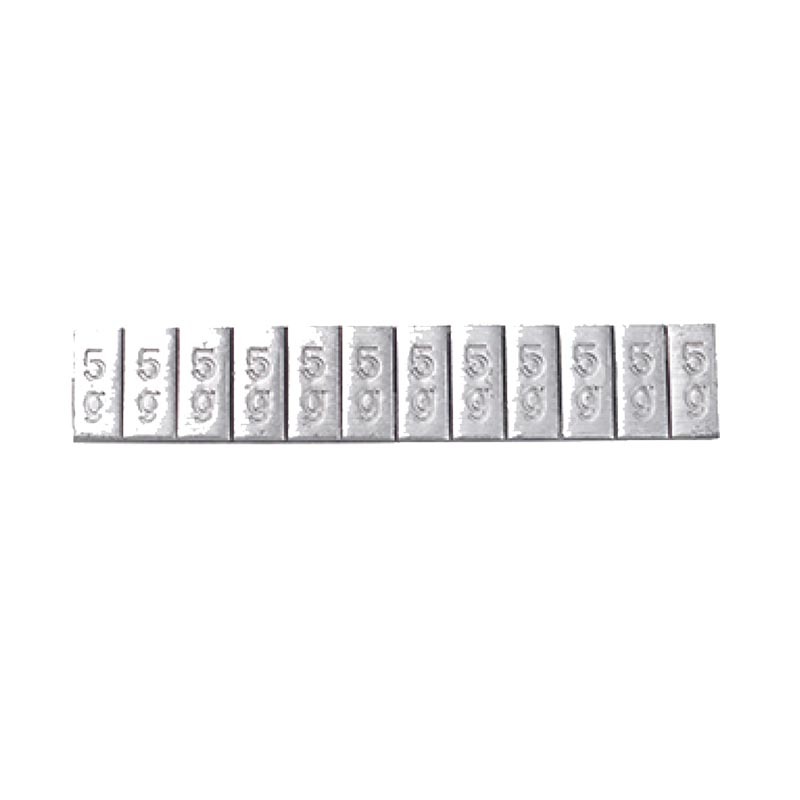

Zinc stick-on weights have emerged as an essential component in the realm of automotive tire balancing, particularly for enthusiasts who utilize aluminum rims. As the automotive industry continues to evolve, the need for quality balancing solutions has become paramount. This article delves into the advantages of zinc stick-on weights, highlighting their unique benefits, ease of use, and environmental considerations, making them an ideal choice for aluminum rim aficionados.

What are Zinc Stick-On Weights?

Zinc stick-on weights are precision-engineered components that adhere to the inner or outer surfaces of wheel rims, primarily used to balance tires effectively. Composed of high-purity zinc, these weights provide critical balancing capabilities, ensuring that vehicles run smoothly and efficiently. Unlike traditional weights, zinc variants offer enhanced performance characteristics that align perfectly with the needs of aluminum rim users.

Benefits of Using Zinc Stick-On Weights

Zinc stick-on weights provide several distinct advantages over alternative materials. This section will explore three crucial benefits: durability, performance enhancements, and ease of installation.

Durability and Longevity

One of the most significant advantages of zinc stick-on weights is their exceptional durability. Zinc is resistant to corrosion and degradation, ensuring that these weights maintain their effectiveness over time. Unlike lead, which can deteriorate under harsh environmental conditions, zinc remains intact, providing long-lasting performance for aluminum rims.

Moreover, the adhesive backing of zinc weights is engineered to withstand various weather conditions, preventing them from falling off and ensuring a reliable balance throughout the weight's lifespan. This durability translates to fewer replacements and less maintenance, saving both time and money for aluminum rim enthusiasts.

Performance Enhancements

Zinc stick-on weights contribute to improved vehicle performance in several ways. Proper wheel balancing is essential for maintaining tire integrity, extending tire life, and enhancing fuel efficiency. When tires are balanced correctly, they distribute weight evenly, reducing vibrations and wear, which can lead to costly repairs and replacements.

Additionally, zinc weights help in achieving a more precise balance compared to other materials. This precision is crucial for high-performance vehicles and those used in competitive settings, where even slight imbalances can affect handling and control. By utilizing zinc stick-on weights, enthusiasts can ensure an optimal driving experience, characterized by smooth handling and responsive steering.

Ease of Installation

Installing zinc stick-on weights is a straightforward process that can be performed by both professionals and DIY enthusiasts. The peel-and-stick nature of these weights requires minimal tools and expertise, making them accessible for anyone looking to balance their wheels.

Proper installation is crucial for optimal performance, and zinc weights come with clear guidelines to facilitate this process. Whether you're a seasoned mechanic or a novice, you'll find that applying zinc stick-on weights is a hassle-free experience, allowing you to maintain your vehicle without unnecessary complications.

Environmental Impact of Zinc Weights

In today's eco-conscious world, the environmental impact of automotive components is an essential consideration. Zinc is a more environmentally friendly option compared to lead, as it poses fewer health risks and is more easily recycled. The use of zinc stick-on weights reduces harmful environmental effects, contributing to greener practices within the automotive industry.

Moreover, many manufacturers adhere to sustainable practices in producing zinc weights, ensuring that they meet environmental standards and contribute positively to the ecosystem. Choosing zinc stick-on weights not only benefits your vehicle but also supports a more sustainable future.

Comparison to Other Weight Materials

While zinc stick-on weights offer a plethora of advantages, it's beneficial to compare them with other commonly used materials such as lead and steel.

Lead Weights

Lead weights have been the traditional choice for tire balancing for many years. However, lead's toxic properties raise significant health and environmental concerns. Additionally, lead weights can corrode over time, leading to performance issues and requiring more frequent replacements. In contrast, zinc weights provide a safer, more durable option without compromising performance.

Steel Weights

Steel weights are another alternative, but they tend to be heavier and less effective in providing precise balance compared to zinc. Steel can also rust, which may compromise its adhesive properties. Zinc stick-on weights, with their superior durability and lighter weight, offer a better solution for aluminum rim enthusiasts seeking quality and efficiency.

Applications in the Automotive Industry

Zinc stick-on weights are not limited to just balancing tires; their applications extend throughout the automotive industry. They can be utilized in various settings, from passenger vehicles to high-performance race cars.

In the world of motorsports, where precision and performance are paramount, the use of zinc stick-on weights is becoming increasingly popular. Their ability to enhance vehicle performance while maintaining a lightweight profile makes them ideal for racing applications where every gram counts.

Additionally, manufacturers often recommend zinc weights for electric and hybrid vehicles, where efficient weight distribution and balance are critical for maximizing battery performance and overall efficiency.

Maintenance and Care for Zinc Weights

Maintaining zinc stick-on weights is straightforward. Regular checks on tire balance and condition should be performed, especially after long trips or harsh driving conditions. If you notice vibrations or uneven tire wear, it may be time to inspect the weights for adherence and integrity.

For the best results, ensure that the rims are clean and free of debris before installation. This will enhance the adhesive properties of the stick-on weights, ensuring they remain securely attached throughout their lifespan.

Conclusion

In conclusion, zinc stick-on weights present a superior choice for aluminum rim enthusiasts seeking durability, performance, and ease of installation. Their environmentally friendly properties and versatility in various applications make them an ideal solution for anyone looking to enhance their vehicle's performance while minimizing environmental impact. By choosing zinc weights, automotive enthusiasts can enjoy a smoother, more efficient driving experience.

Frequently Asked Questions

1. Are zinc stick-on weights easy to install?

Yes, zinc stick-on weights are designed for easy installation. They come with a peel-and-stick adhesive backing, making them accessible for both professional and DIY applications.

2. How long do zinc stick-on weights last?

Zinc stick-on weights are durable and can last throughout the life of the tire, provided they are installed correctly and the rims are well-maintained.

3. Can zinc weights be used on all types of rims?

Zinc stick-on weights are suitable for most types of rims, including aluminum and steel, making them a versatile option in the automotive industry.

4. What are the environmental benefits of using zinc stick-on weights?

Zinc weights are less toxic than lead and are more easily recyclable, making them a more environmentally friendly option compared to traditional weights.

5. How can I ensure the best performance from my zinc stick-on weights?

To ensure optimal performance, regularly check the weights for adherence, keep your rims clean before installation, and monitor tire balance and condition regularly.

TAG:

Previous:

Related Posts

Global automotive wheel balance block industry

The global market size of automotive wheel balance weights in 2024 is approximately 4.92 billion yuan. It is expected to maintain a steady growth trend in the future